Centurion SI-SC machine for fresh food industry

VHVP offers the best solutions for your fresh food business

As a producer in the food industry, you know better than anyone that the sector’s bar is high: efficiency and high uptime are of paramount importance. Additionally, the ‘total cost of ownership’ is an increasingly determining factor when purchasing a new packaging machine. VH Vertical Packaging is a specialist in the development, manufacture, installation and maintenance of sustainable packaging machines for packaging fresh lettuce and vegetables, including cut, washed and mixed. Freshly processed potato products are packaged, such as fresh fries, slices, large potatoes, etc.

The production and packaging of fresh products is carried out under very strict quality and hygiene rules. The shelf life of these products is extremely limited, which means they must always be processed and packaged quickly. VHVP has developed the Centurion Fresh specifically for this sector of the market. A machine that meets your requirements perfectly, because we know the specifications of vertical packaging in your industry through and through. You can always count on expert advice and, where required, customisation can be provided based on your needs and specifications. Needless to say, many food producers use VHVP machines.

Value for money met Centurion Fresh

Centurion Fresh is a user-friendly machine, easy to operate and with short set-up times. With high uptime, integrated gas flushing, swirl protection and modest operating and maintenance costs, a valuable investment. When processing fresh products, bags can be used in both consumer and hospitality/wholesale sizes.

Extremely high standards must be met when processing fresh products

Each package must be leakproof and gas flushed if required, to guarantee shelf life. Depending on the client, the residual oxygen value is between 1 and 2 percent.

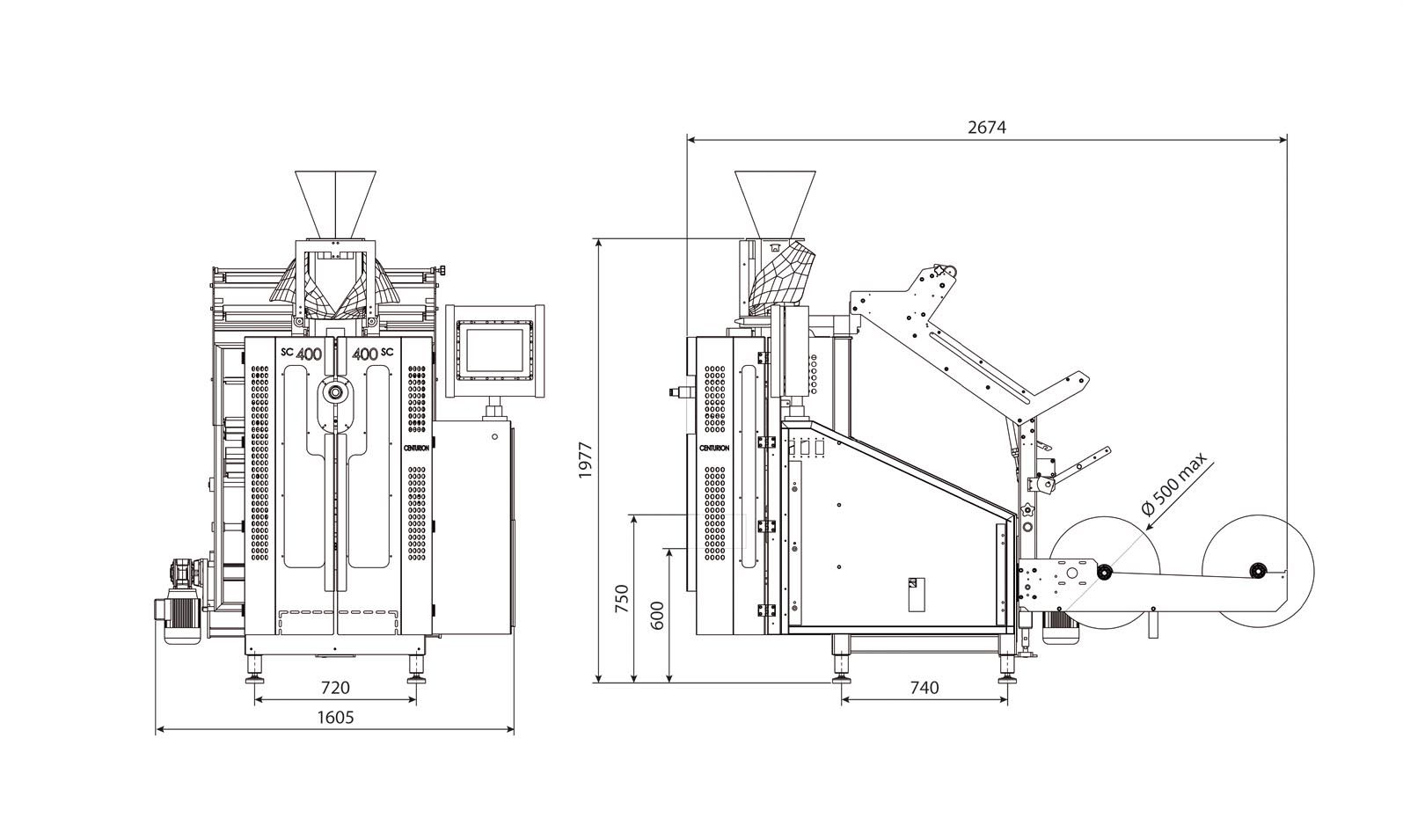

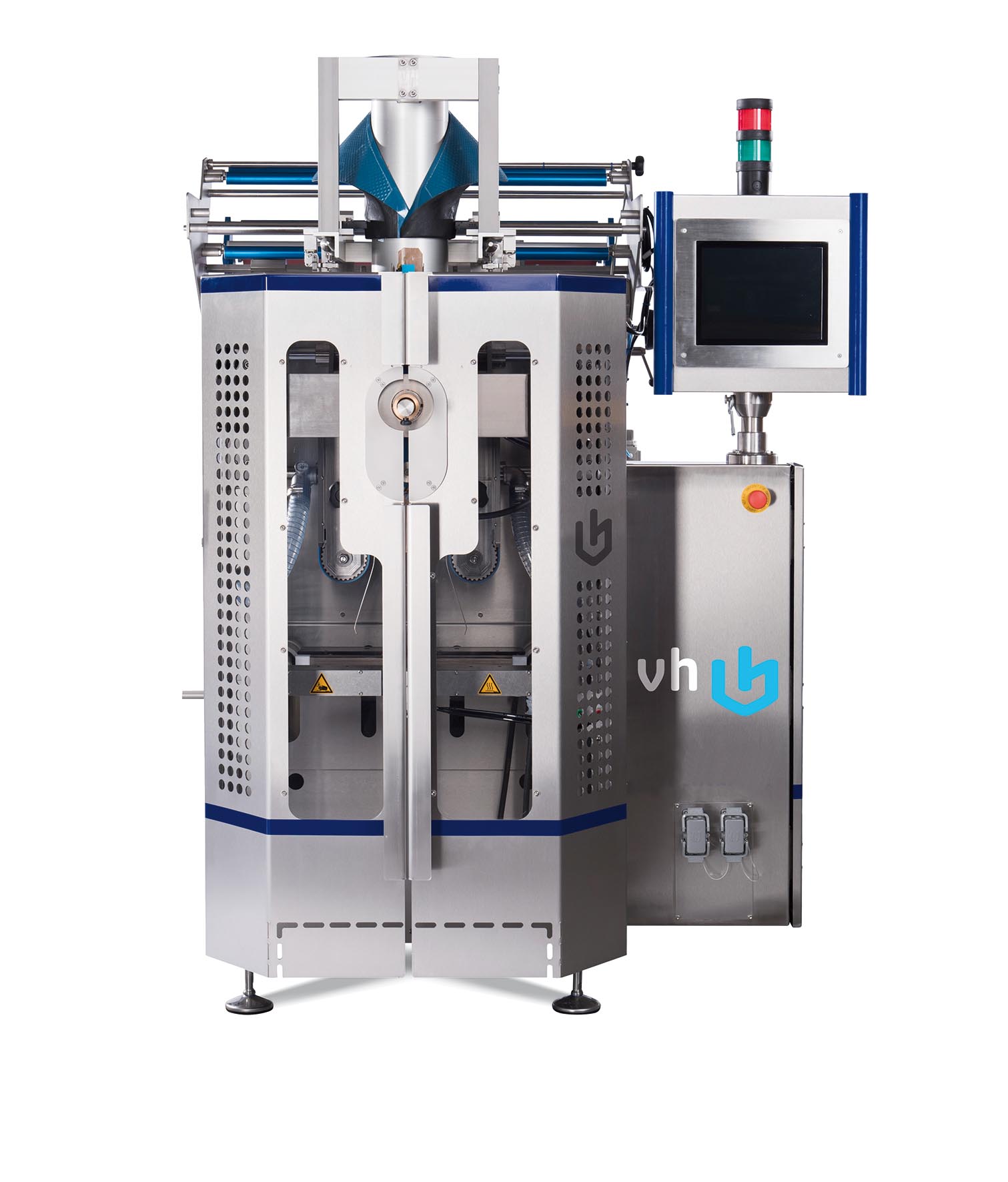

Centurion SI & SC vertical packaging machines

User-friendly and accessible

The Centurion Fresh vertical packaging machine is a top performer in the premium segment. The machine’s design exudes simplicity and class, where user-friendliness and accessibility are paramount. A superior uptime of over 98.5%, low running costs and low maintenance, are the great strengths of the Centurion SI and SC.

This machine is equipped with our online Remote Engineer system, reducing the numbers of visits from our engineers. The operating system is highly advanced and easy to use. There is one central servo drive that is able to control three axes.

Familiar with the ins and outs of your industry

Processing fresh products imposes high demands on your machine

The machine needs to deliver efficiency when packaging different types of fresh sliced lettuce and vegetables, and also fresh processed potato products. To prevent contamination, regular and frequent cleaning is carried out, which means that the environment is often damp.

Centurion Fresh performs faultlessly in cold and wet production areas. Slippage due to high levels of friction is not an issue due to the vacuum supported belt tensioning system. Smooth label changes minimise loss of time. A reassuring thought when fulfiling orders under pressure. Fresh vegetables, lettuce and potato products are natural products, whose weight, shape and composition always vary. It is important this fresh produce is packaged leakproof and gas flushed, in order to guarantee their shelf life.

If the product swirls when gas is added, then this can cause contamination to become trapped in the seals, thereby increasing the risk of leakage. The Centurion Fresh guarantees that the volume is properly distributed, and always fits perfectly into the packaging. Product damage is kept to a minimum.

With Centurion Fresh, you can respond to changing market demands

Food producers like to respond quickly to specific requests from clients. The importance of minimizing downtime when changing labels, for example. When the market demand is constantly changing, the ability to be flexible and able to adapt quickly is highly desirable. With Centurion Fresh, you will always be well prepared: a smooth changeover between different types of packaging, resealable or not, ensures a great amount of flexibility and continuity.

Centurion Fresh

- Provides a reliable gas flow, if appropriate

- Prevents speed loss

- Prevents blockage in funnel

- Prevents leakage

- Prevents contamination

- Prevents seal contamination

- Prevents product damage

- Prevents moisture and sticking problems

Made entirely of stainless steel, easy to clean, compact construction

– IP 65 Display, 12 inch

– Spacious electrical cabinet, heating and ventilation

– Top-quality finish

– Bag widths from 70 to 440 mm, various bag types supported

– Extremely stable group of seal jaws, shortest film head, and high-tech film balance

Different types of packaging

All bags are available in both consumer and catering sizes. Other packaging formats can be discussed on request.

Overview of practical applications

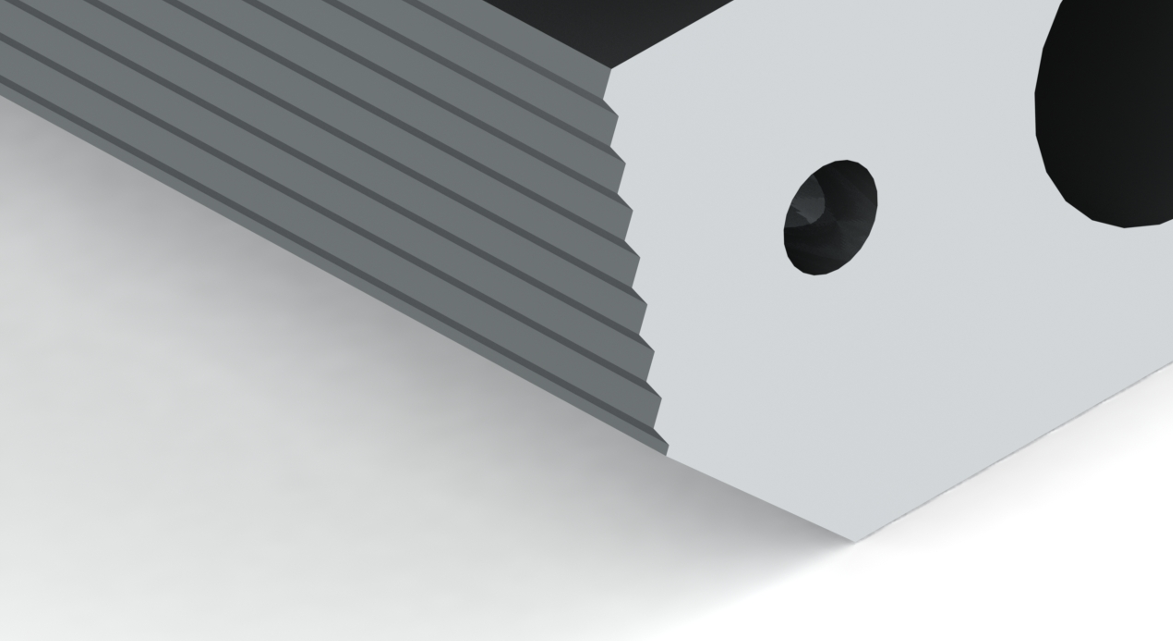

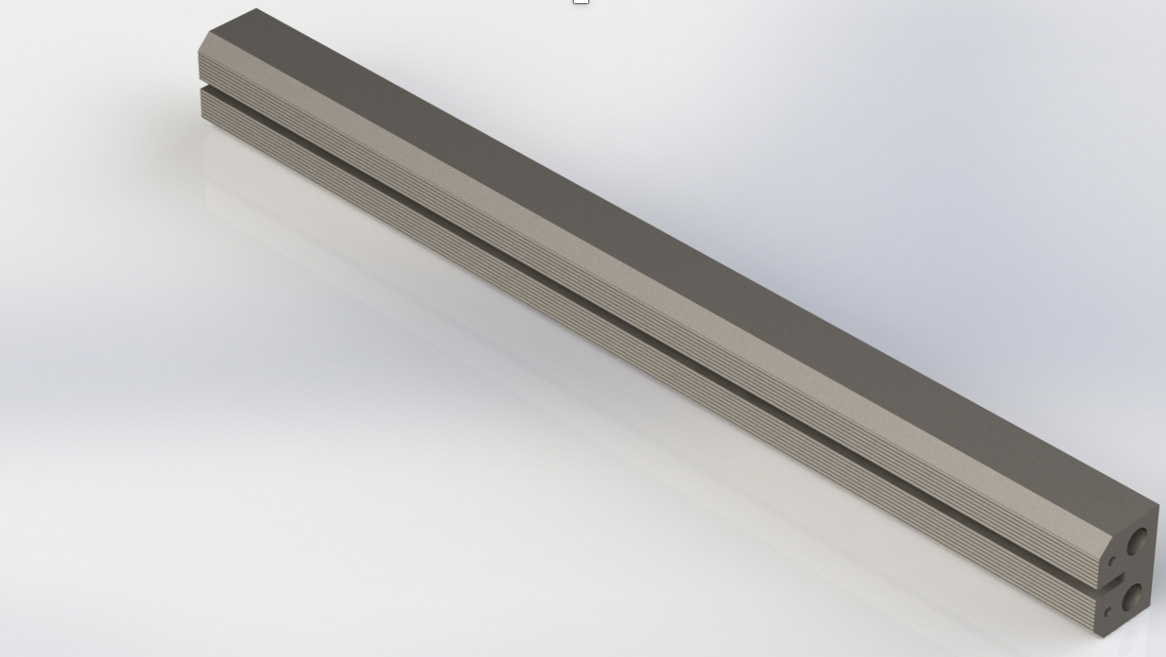

Sealing bars

Deep serrated sealing irons are important. Together with the correct seal jaw pressure, sealing bars ensure that packaging is leakproof. This system guarantees that packaging is always properly sealed in the event of seal contamination, even in a wet environment. Where there is a lot of product overfill on an intermittent application, a collection clamp is used: this closes the packaging before sealing. All overfill is collected.

Our machines are suitable for processing alternative packaging materials.

Fresh packers

Suitable for both consumer packaging and packaging for the catering and wholesale sectors.

Depending on bag type, length and weight, the following options are available on Centurion Fresh:

- Bag support: for the correct seal security at higher weights.

- Tap and vibrate system: for settling bulky products into pyramid shapes.

- Special formatsets: anti-stick, integrated funnel, high-density air outlet.

- Gas supply system: depending on choice, flow control and/or inline check, or as special

anti-swirl supply system.

Allgro fully converted to Centurion Fresh

As a production company in the fresh sector, we consciously choose to work together with VH Vertical Packaging. VH Vertical Packaging is a reliable and flexible partner. For example, the packaging machines of VH Vertical Packaging are not only easy to use, but also ensure that format changes can take place quickly.

The good service, the expert advice and the knowledge of the market ensure that we are happy to work with them.

Chris Raes

Production manager Allgro

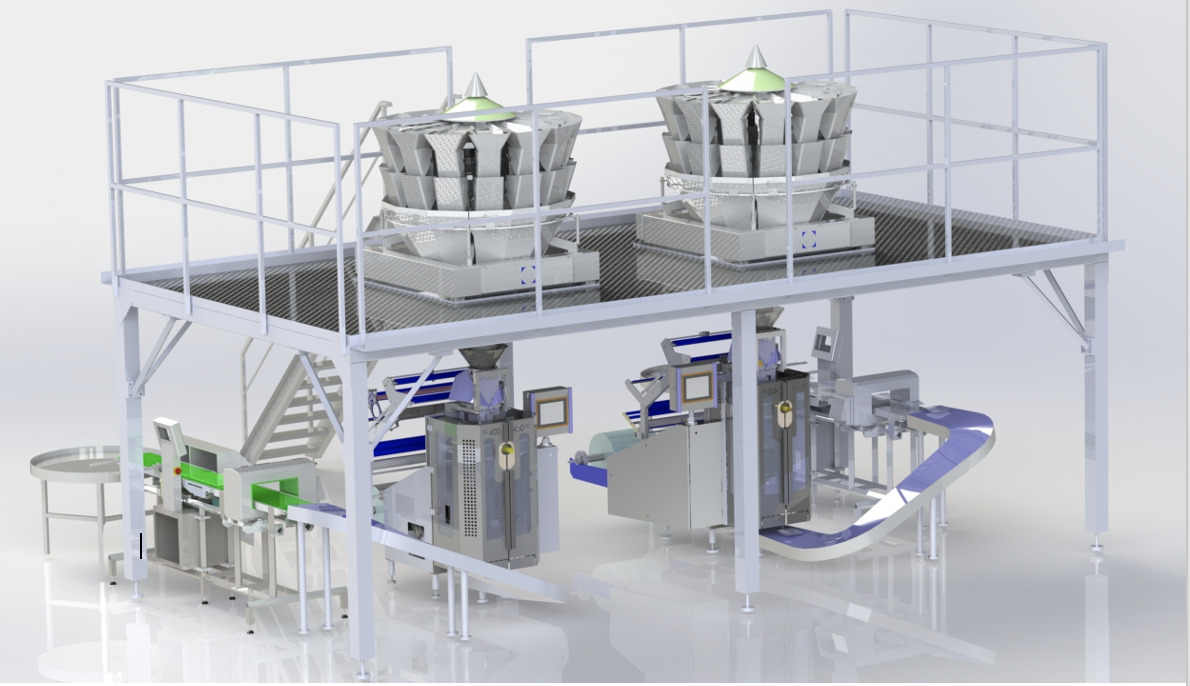

Turnkey solution for the fresh food sector

Complete high-efficiency packaging lines

VH Vertical Packaging also offers turnkey solutions. Based on your requirements, a complete, customised packaging line is developed with the greatest care, with guaranteed high capacity and operational reliability. VHVP takes complete control, either from the feeding belt, or after the feeding belt. This varies per client, depending on the existing processing installation. From engineering to installation and commissioning, you will have just one dedicated point of contact. This is carried out in phases:

- Engineering in both 3D and 2D.

- Delivery of: elevating systems, floor construction / platform construction, weighing systems

with associated partners such as Multipond, packer with accompanying options (printing

and label technology), output systems with metal and checkweigher detection systems.

This means that you can be assured of an optimally efficient, future-proofed packaging line with a long service life. It goes without saying that support, maintenance and service are an integral part of our business.

Full supervision by VH Vertical Packaging

For you, this means: short lines of communication, clear agreements, high-quality equipment and, above all, a pleasant collaboration with professionals who have a high level of experience of your sector. After installation of the packaging line, all your technical staff and operators will receive the appropriate training.

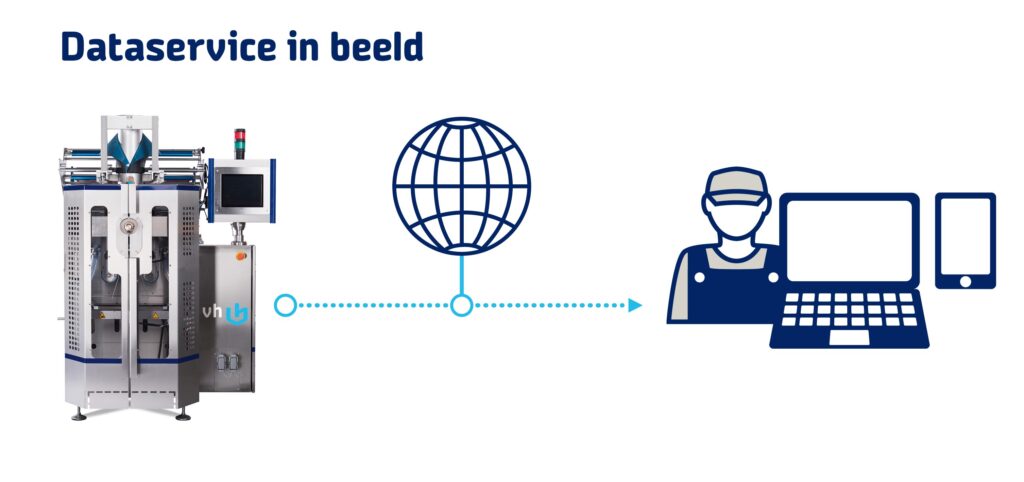

Optimal support with MyCenturion

Packaging machine with a high uptime

MyCenturion from VH Vertical Packaging enables you to continuously monitor the performance of your Centurion packaging machine. Based on reports received from the control system on, for example, film standstill or film changeovers, continual improvements which lead to higher efficiency can be implemented. This system also allows for preventive maintenance to be predicted extremely efficiently, thereby keeping downtime and malfunctions to a minimum. Routine maintenance is always transparent, so that wearing parts can be replaced in good time.

Basic functionalities

We record all basic functions in a so-called machine master card. This basic data can be different for each machine. Recordings are subdivided into different main groups:

- Basic information such as heights, line integration, peripherals and standard options

- Software versions with accompanying custom-made updates

- Mechanical issues, both standard modifications and custom-made modifications

- Format and funnel information (including PDF film drawing)

- Recording the documentation of each master card. Such as layout, e-scheme,

situational photos, CE declaration (generator)

Objectives of My Centurion

– Higher uptime of packaging machines

– Highest possible output of packaging machines

– Optimal operator convenience

– Effective guidance from VHVP

Extra functionalities

– Tracking mechanical improvements

– Tracking mechanical developments

– Tracking software improvements

– Tracking software developments

– Tracking purchase orders

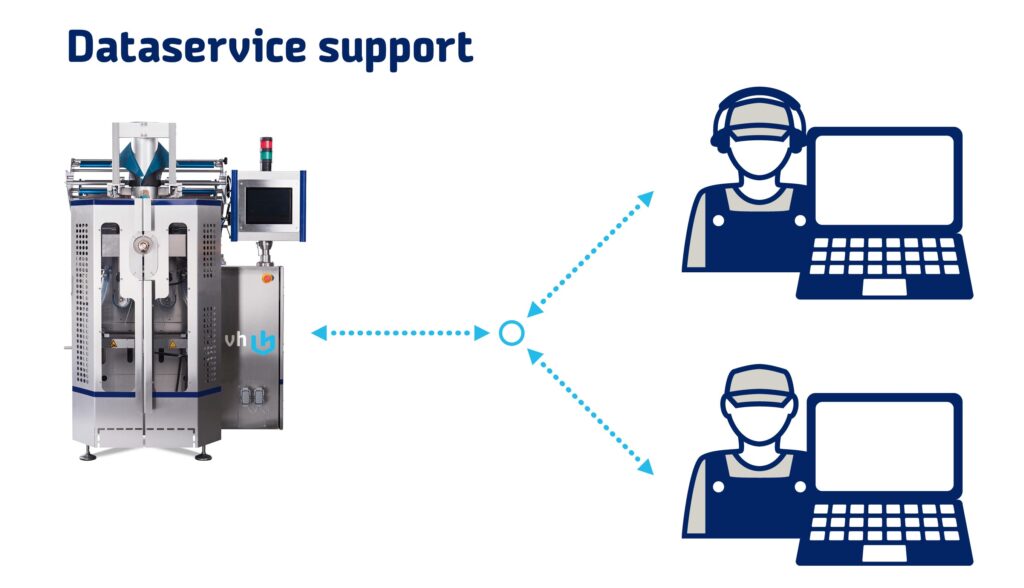

MyCenturion remote communication

Various communication types are supported by VH Centurion: OPC UA, MQTT, VNC Server and Mail Server.

OPC UA

Open platform communications (OPC) (UA). An external MES system collects data from the machine. OPC UA cannot be used in combination with MQTT.

MQTT

MQ Telemetry Transport (MQTT). MQTT can currently only be used to send data to MyCenturion.

VNC Server

Virtual Network Computing (VNC). VNC Server can be used to take over screens from other machines and peripherals, on condition that a VNC Server is running on the remote machine.

Mail Server

The machine will forward the data to the appropriate email address. An events list can be included.

Tell me more about Centurion Fresh

We are happy to give you more detailed information about this machine

For more information about your specific packaging requirements, please contact our specialists.

Freek Jacobs, Marcel Wetemans and Rick Hartmann are at your service. They will be happy to demonstrate the efficiency and high uptime of our Centurion machines. Call +31 (0) 495 550 733, send an email to sales@vhnl.com or use the response form.

Freek Jacobs

Marcel Wetemans

Rick Hartmann