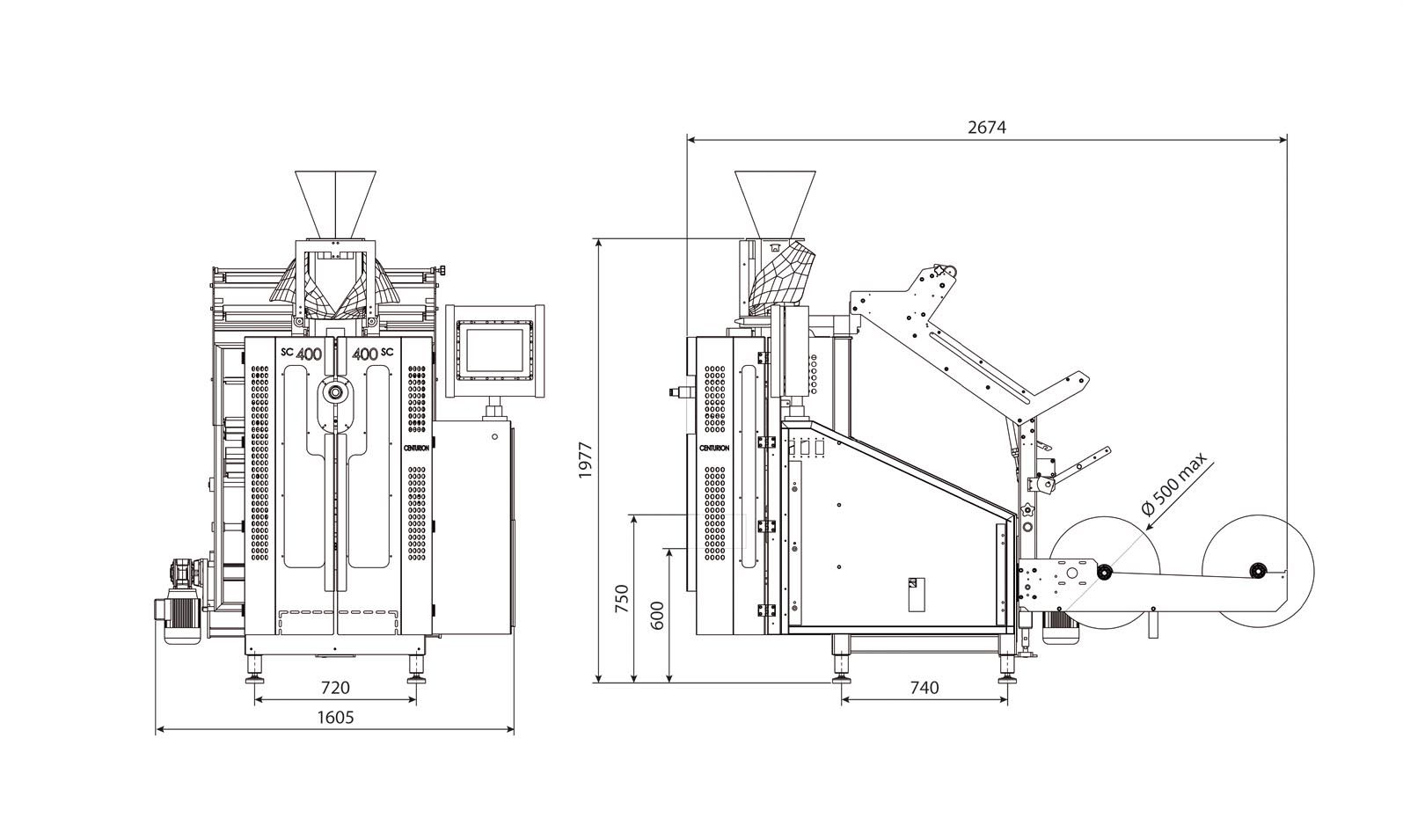

Centurion SI-SC machine for frozen industry

VHVP offers the best solutions for your frozen business

As a producer in the food industry, you know better than anyone that the standards in this sector are extremely high: efficiency and maximum uptime are vital. In addition, the total cost of ownership is an increasingly decisive factor when purchasing a new packaging machine. VH Vertical Packaging is a specialist in the development, construction, installation and maintenance of sustainable packaging machines.

The Frozen group covers a broad segment. This includes items that are packed for B2B, and items that are packed for the retail market. Segments within this group can be divided into vegetables, fruit, potatoes, meat and fish. Each segment has its own specific characteristics.

The larger companies have customers in retail and B2B. The smaller customers often specialise in either one or the other. Deep-frozen products are packed in bags, then in boxes or crates.

Centurion SI & SC vertical packaging machines

User-friendly and accessible

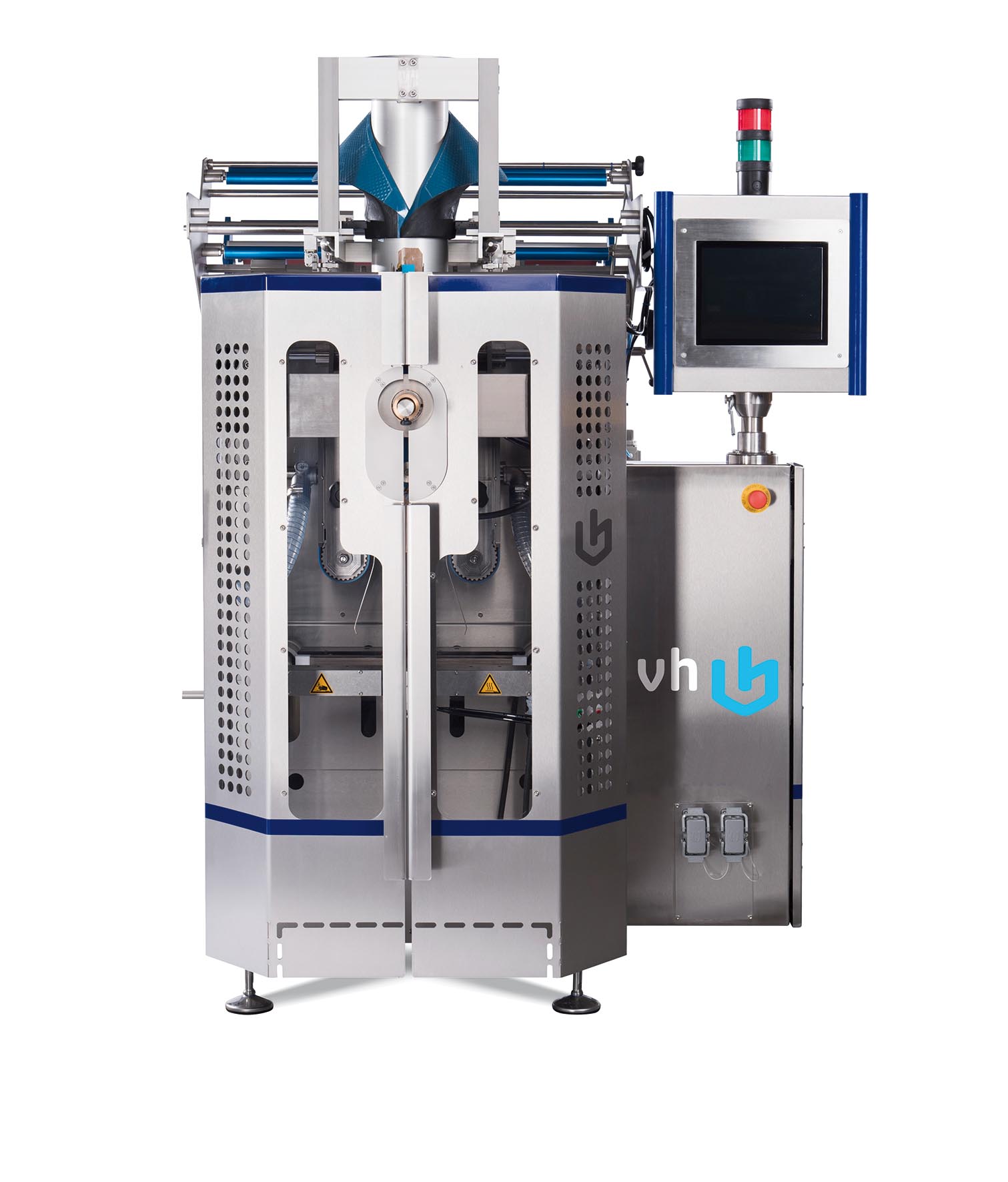

The Centurion Frozen vertical packaging machine is a top performer in the premium segment. The machine’s design exudes simplicity and class, where user-friendliness and accessibility are paramount. A superior uptime of over 98.5%, low running costs and low maintenance, are the great strengths of the Centurion SI and SC.

This machine is equipped with our online Remote Engineer system, reducing the numbers of visits from our technicians. The operating system is highly advanced and easy to use. There is one central servo drive that is able to control three axes.

Familiar with the ins and outs of your industry

Processing deep-frozen products makes high demands on your machine

The machine needs to deliver efficiency when packaging deep-frozen products. Processors all have their own requirements and bottlenecks.

Requirements and bottlenecks in processors

- Cold environment

- Wet environment which causes:

– High friction of the film on the packer, forming tube etc., which can cause slippage or ripped bags

– The packers are often damaged due to aggressive cleaning agents - High volume to be processed, in combination with high production pressures

- The requirement to process films that are as thin as possible films can make sealing difficult. Fine tuning is required

- There should not be too much air in the pack, air expulsion is required

- High cost of ROPEX/PTC sealing system

- Speed in small packaging is high, and the packers must also be able to handle large packaging, which means a “large model” machine must be chosen

- Risk of open seals due to not carrying out maintenance to sealing system on time

- Piston effect when pouring the product can result in open longitudinal seams

- Some segments require the packing of sharp products, such as flatfish, chicken thighs/fillets. During dispensing, these can pierce the film

- Environment causes foils to cool rapidly before processing

With Centurion Frozen you can respond to changing market demands

Being able to respond quickly to the specific demands of retailers is important. When the market demand is constantly changing, the ability to be flexible and able to adapt quickly is highly desirable. With Centurion Frozen, you will always be well prepared: a smooth changeover between different types of packaging, resealable or not, etc. ensures a greater amount of flexibility and continuity.

Centurion Frozen

- Easy to operate

- Shorter set-up times

- Optional unique sealing system available: OMNISEAL

- Less maintenance and therefore lower costs

- Higher uptime and 100% easier to use

- Completely new and unique

- Production performance in a simple MyCenturion System

- Integration of all necessary bag treatment systems

- Frozen format prevents piston effect

Made entirely of stainless steel, easy to clean, compact construction

IP 65 Display, 8.4 or 12 inch

– Spacious electrical cabinet, heating and ventilation

– Top-quality finish

Bag widths from 50 to 440 mm, various bag types supported

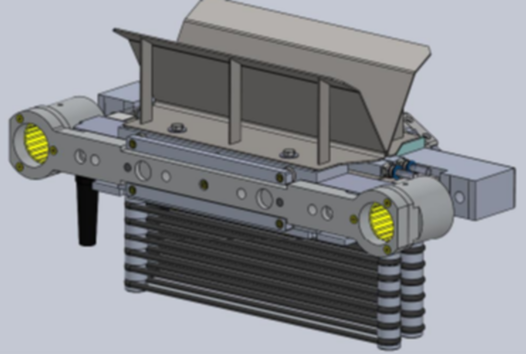

– Extremely stable group of seal jaws, shortest film head, and high-tech film balance

Different types of resealable packaging

Overview of practical applications

Sealsystems

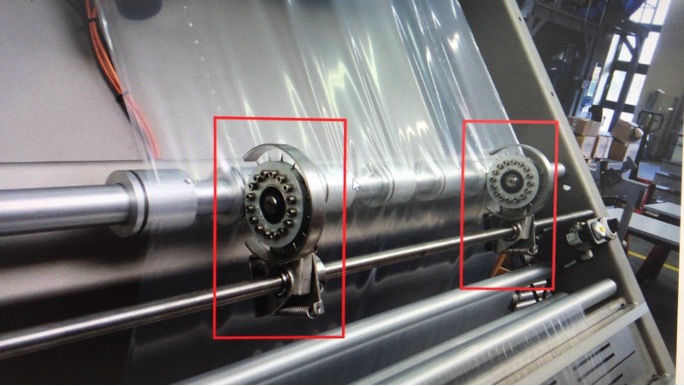

Choose either the traditional PTC sealing system or the new OMNISEAL. Both systems are ideally suited to LDPE film.

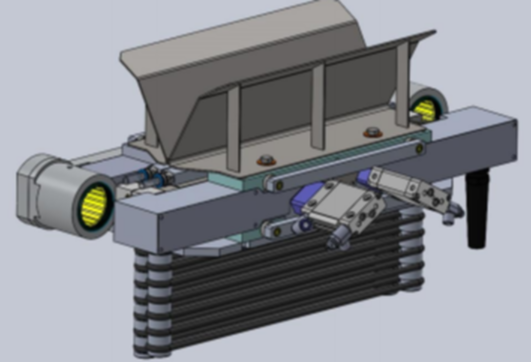

Benefits of OMNISEAL

- No Teflon tape

- Approx. 1.2M bags before strip change is required

- Downtime of 1x per shift to 1x per month

- No sealing edges

- Easy to adjust

- Cutting before sealing

- Collection trays

- Perfect seal cooling

Perforation options

Depending on bag type, length and weight, the following perforation options are available for Centurion Frozen:

Inline Günter perfo systeem Inline perforatie

- Easy opening on the cross jaw

- Bag turner: for optimal delivery to secondary packing stations (case packers).

Flap that closes at the seal and collects the product, protecting the film.

Hygiene

The multihead weighers and feeders are wet-cleaned. The packer needs to be protected against this. VH Vertical Packaging recommends the appropriate method for each situation:

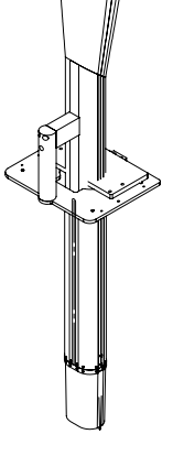

– The machine can be positioned on the rails, and the space above is closed off during cleaning. There is a top plate on the machine to protect the film during production.

– The machine is fully roofed and fitted with a hopper and a drip edge. During production, the film remains clean and the machine is fully protected during cleaning.

– The machine is equipped with a changeover system, and the end tray is integrated into the platform. It can be closed off with a cleaning tube.

VH advises per individual case to ensure the best possible result.

LED – VH

For optimal operation of the line. There are often several lines that are served by one operator. Visual display of signals, such as pre-notification for end of film roll, are extremely practical and optimise efficiency.

Case packer systems

VH advises per individual case to ensure the best possible result. VH can connect the Centurion to all case packer systems to create an integrated whole. If required, VH offers the option to equip the machine with a roto tipper. This ensures that the packaging is placed in the case packer in the correct way, with the seal seam either at the bottom or top.

Fully converted to Centurion Fresh

Easy to operate system, high efficiency and a hygienic design are features that define the VH Centurion. The reliable vertical packaging of thousands of packages every day in a production environment requires an extremely high level of operational reliability, and a supplier who is available 24/7 to offer support whenever required. erational reliability, and a supplier who is available 24/7 to offer support whenever required. VH Vertical Packaging is a very agreeable partner to work with, a strong company that moves forward at full speed, and is always prepared for the future!

Ben Verheyen

Head of technical service Flanders Food Productions

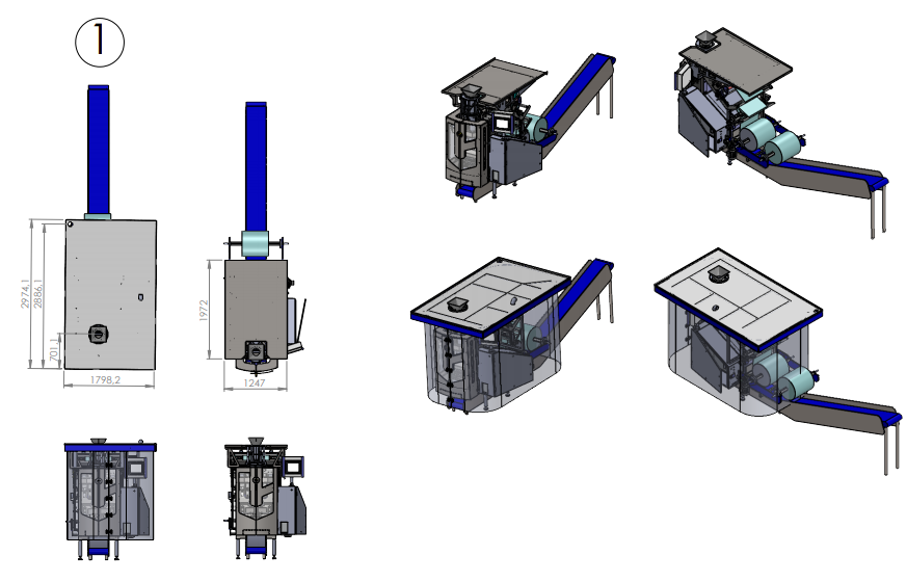

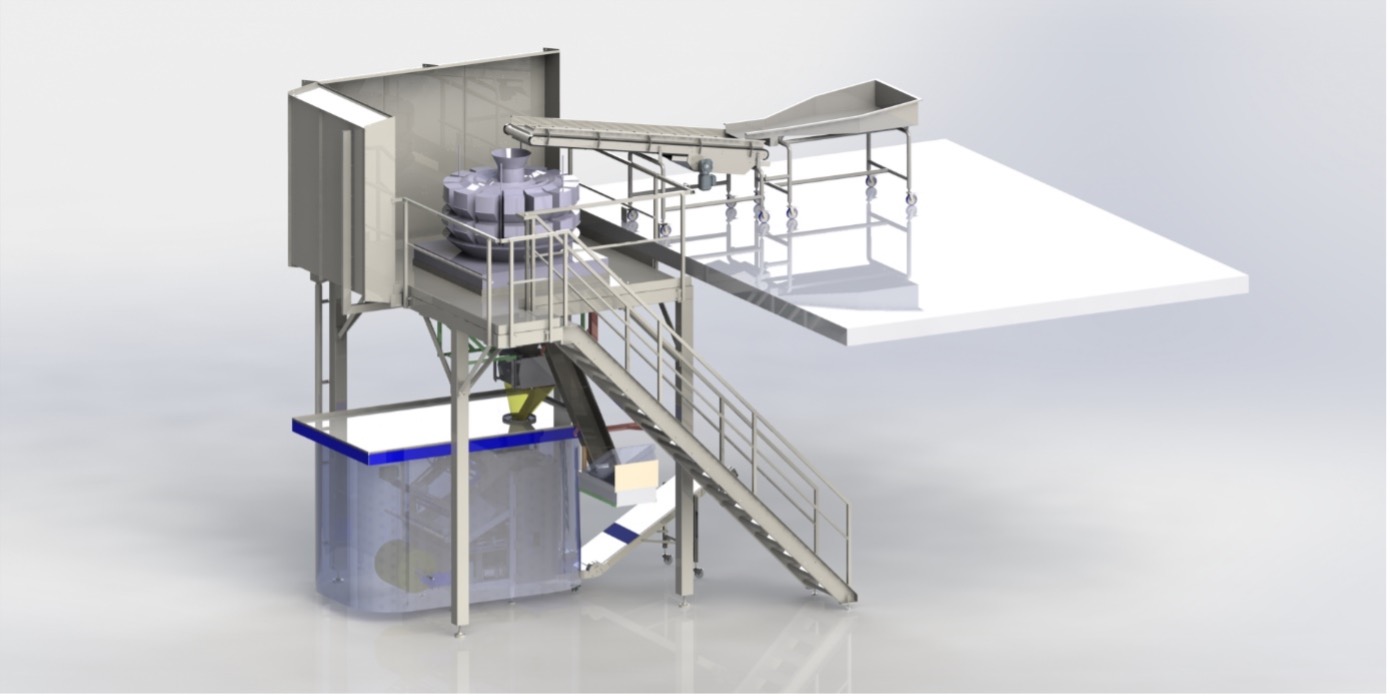

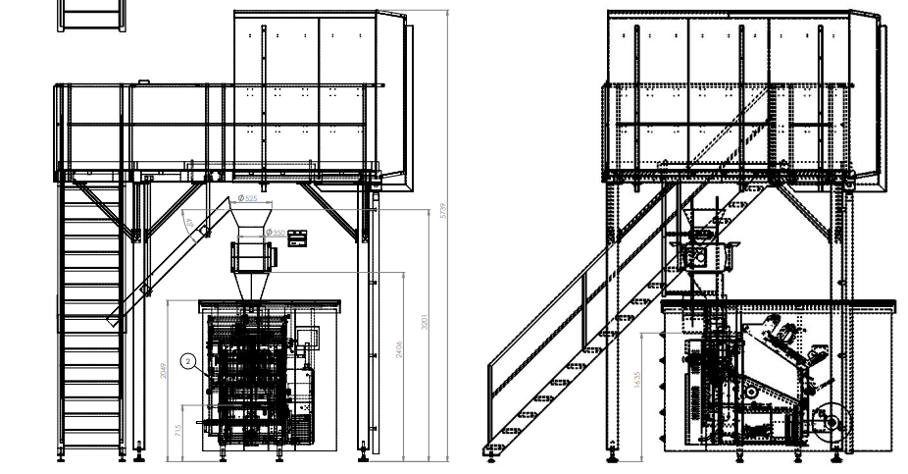

Turnkey oplossing voor de frozen sector

Complete packaging lines with high efficiency

VH Vertical Packaging increasingly supplies turnkey solutions. Based on your requirements, a complete, customised packaging line is developed with the greatest care, with guaranteed high capacity and operational reliability VH takes complete control, starting from the infeed belt, or after the infeed belt. This varies per client, depending on the existing grating installation. From engineering to installation and commissioning, you will benefit one dedicated point of contact. We take a phased approach:

- Engineering in both 3D and 2D.

- Delivery of: elevating systems, floor construction / platform construction, weighing systems with associated partners such as Multipond, packer with accompanying options (printing and label technology), output systems with metal and checkweigher detection systems.

This means that you can be assured of an optimally efficient, future-proofed packaging line with a long service life. It goes without saying that support, maintenance and service are an integral part of our business.

Full supervision by VH Vertical Packaging

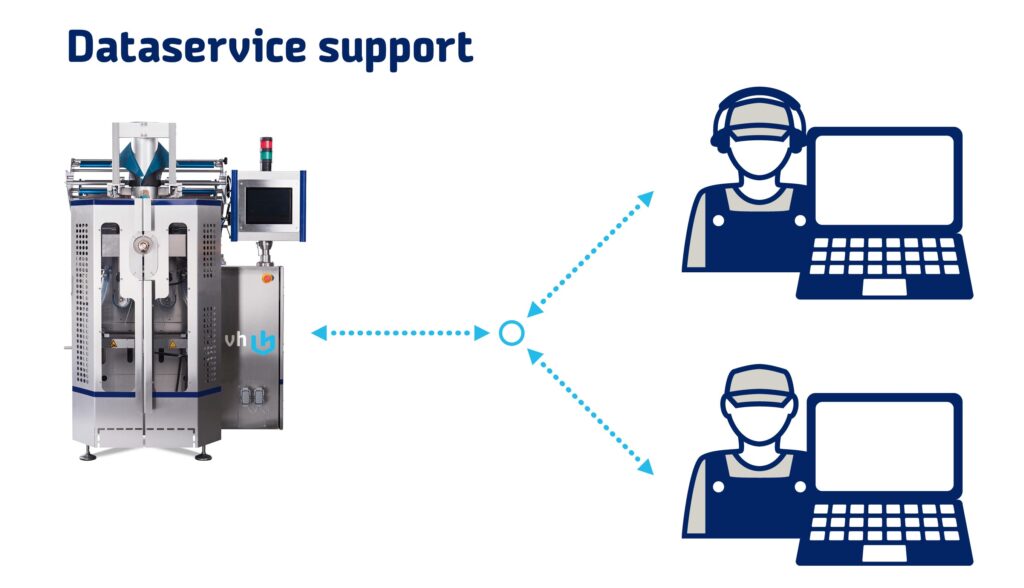

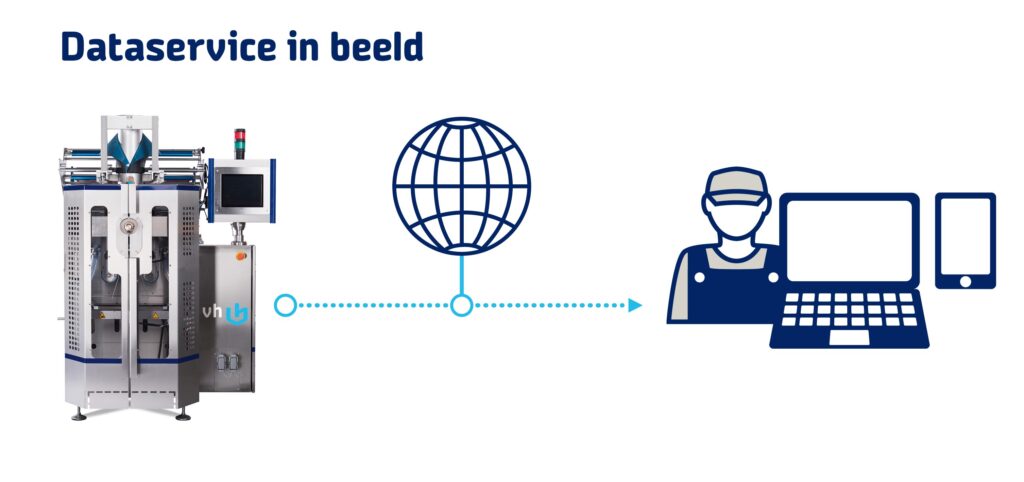

Optimal support with MyCenturion

Packaging machine with a high uptime

Basic functionalities

We record all basic functions in a so-called machine master card. This basic data can be different for each machine. Recordings are subdivided into different main groups:

- Basic information such as heights, line integration, peripherals and standard options

- Software versions with accompanying custom-made updates

- Mechanical issues, both standard modifications and custom-made modifications

- Format and funnel information (including PDF film drawing)

- Recording the documentation of each master card. Such as layout, e-scheme, situational photos, CE declaration (generator)

Objectives of My Centurion

– Higher uptime of packaging machines

– Highest possible output of packaging machines

– Optimal operator convenience

– Effective guidance from VHVP

Extra functionalities

– Tracking mechanical improvements

– Tracking mechanical developments

– Tracking software improvements

– Tracking software developments

– Tracking purchase orders

MyCenturion remote communication

OPC UA

MQTT

VNC Server

Mail Server

Tell me more about Centurion Frozen

We are happy to give you more detailed information about this machine

For more information about your specific packaging requirements, please contact our specialists. Freek Jacobs and Marcel Wetemans are at your service. They will be happy to demonstrate the efficiency and high uptime of our Centurion machines. Call +31 (0) 495 550 733, send an email to sales@vhnl.com or use the response form.